Before I even start this blog post – I will admit, I MAY BE BIASED… and somewhat ‘rigidly’ so too.

Before I even start this blog post – I will admit, I MAY BE BIASED… and somewhat ‘rigidly’ so too.

I was raised by parents who demanded I be truthful, honest, transparent. They only wanted the BEST for me – but also taught me that I had to be and do my (personal) best to earn it. (#bestbuildings)

They showed me what it looked like to be a good steward, to NOT WASTE, to do things right and do the RIGHT thing.

They encouraged me to THINK, to not TAKE everything as fact just because someone said so, to do MY OWN homework and research to make up my own mind, within a context of lasting-over-time. i.e. “Be in it for the long haul”!!

They showed me the importance of making sure the things meaningful in my life had value, integrity, durability, quality and purpose, and that that would only come if I GAVE to them in the same way… from the people I could choose to be, work, live and play with, to the “things” I could choose to own, operate, use, share and/or have stewardship over.

So quality, value, durability, integrity, flexibility, adaptability and sustainability, just to name a few, would become constant barometers in the litmus tests of whatever and whenever I had the freedom to make choices on or about. (#strongbuildings).

And so it goes for anything associated with TEAM PERKA, from the products we offer, the teammates we attract, the service we give and the care with which we undertake each of life’s moments. (#integrity)

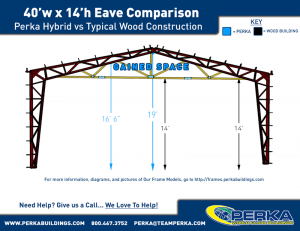

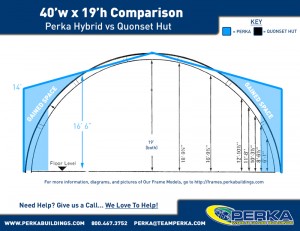

So in this biased sense, we are committed to the goal that the PERKA BUILDING ‘system’ offers the highest value as an investment, the most strength for durability over time, the most flexibility to adapt to any building need, as well as being easy and simple to deal with for any modifications, finishing or maintaining needs. Whether it be during the build process or even months, years or decades in the future; your PERKA BUILDING will be able to grow WITH YOU!

Those main attributes of strength, flexibility, value and simplicity are the things we hear time and again, of what is important to builders and building owners alike…

RIGID FRAME BUILDINGS

Now let’s take the RIGID frame (plate beam) type of building design for example. It’s own name pretty much points to fact that they are probably not going to be very “easy or flexible to deal with”. We realize that it’s a technical and engineer based description, unfortunately our experience has also made it the descriptor for other things as well.

Despite being totally committed and convicted about the many many great things in a Perka Wood Steel Hybrid Building, we are not always able to fully convey the information, experiences and testimonials needed to help some folks fully comprehend the many benefits and longer term returns on this type of Wood/Steel Building investment.

In an effort to still be able to serve as many clients as we can, we still look for the best, most affordable alternative and sometimes yes, even “rigid frame” type building sources, so that we could have yet more options for those who still want to deal with an organization like TEAM PERKA, that has a long standing history of integrity for standing behind their products, commitments and obligations.

In the many (Perka) Rigid Frame buildings we supplied over the years we can say quite candidly that the majority of them has offered up at least one significant challenge that either cost our client or ourselves MORE money than we originally counted on spending. (And this does not even take into account the generally speaking larger foundation requirements needed that should be part of the decision up front, though often forgotten check out: http://www.perkabuildings.com/more-on-rigid-frame-designs-caveat-emptor/.)

Whether it was not having a door or window positioned in the right place and then having to jump through hoops and verifications to resolve it, or dealing with part after part of the building materials, that was NOT pre-assembled, NOT properly labelled, not fabbed accurately, not pre-welded, not pre-punched or just NOT there. The fact that we had these issues was not the worst of it… ‘stuff happens’, we can adjust to that.

— Unfortunately the worst part was what we needed to do to “fix or resolve” these issues. It was not a matter of simply pulling out some tools to modify a few pieces and fasten them back up the way they were suppose to be. No. We had to first get clearance from engineering to make sure we were not altering the integrity of the originally designed building SYSTEM, since the building’s TOTAL LOAD capacity is pretty much 100% dependent on EVERY part being the part it’s suppose to be, in the place it is suppose to be in and installed the way it is suppose to be installed. ANY deviation of any of these on a RIGID FRAME SYSTEM DESIGNED BUILDING, can lead to reduced load capacity and potentially compromise the building’s ability to withstand their intended snow, wind or seismic loads. That process is generally not an “easy or simple” one. The flexibility, if any, of this design, in our experience, is virtually non existent.

Here are a few more observations.

Are Rigid frame buildings strong? Sure they are — but only as strong as they are “built” to the exact specifications of the manufacturer. NO DEVIATIONS. No modifications. No after the fact alterations, changes, add ons… at least NOT without getting things cleared. And you may as well allow a chunk of time and most often a good chunk of some more hard earned money for that process.

Are Rigid frame buildings flexible? Yes, but only to the extent you have torches and welders to modify things AFTER you get approval, and able to afford the typically HIGH COST of beefing things up; from the extra labor and the need for more or newer (STEEL) parts to accommodate the change. (Which typically can only be purchased from manufacturer.) “No substitutes”!

Are Rigid frames EASY and SIMPLE? Sure, but only if you know EXACTLY what you want UP FRONT, and basically “never” want to change ANYTHING. If you don’t meet those two criteria… you may as well count on complexity, difficulties, delays and worst of all alot MORE MONEY. Not just a little. In some cases, ALOT!

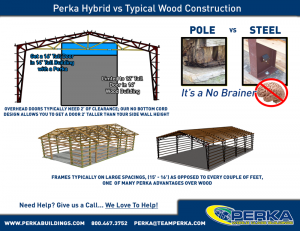

Are Rigid frames aesthetically pleasing? If you like the main option of your outer shell to be JUST STEEL. Then yes. Of course you can COVER these with decorative materials — but don’t think about “saving” the steel to put something else on instead, to save some time and money. It won’t happen. Unless you planned this from the start, you will either have to leave the steel sheeting on, and PAY EXTRA to cover it – or pay more for special engineering and structural beef ups to be able to remove the sheeting to allow you to put something else more aesthetically appealing instead. It is not exactly a “value added” option!

Are Rigid Frames less costly? Yes. Sometimes. – And again this is dependent on you having to know (TODAY) EXACTLY what you want, and with NO PLANS to change pretty much ANYTHING! (Hence “RIGID frames”??!!). Otherwise — NO. Pure and simple they will cost MORE. And in some cases, as we experienced, by the time you get the job totally completed, ALOT more.

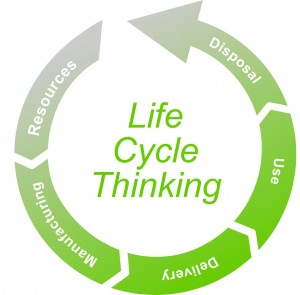

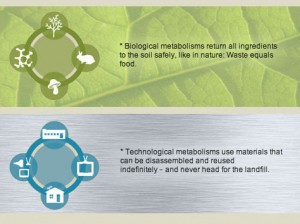

In this day and age, where our society faces regular concerns about threats of harsh weather conditions, insecurity about finances, rapid changes in individual and collective life situations be it family, work, technology, location or purpose, it appears vital that our better choices will be able to offer strength to endure adversity and change, flexibility to be able to adjust whenever and however to whatever conditions that pop up, and to do this affordably, with an awareness for sustainable practices and a continued commitment to maintaining our assets for the long haul. Yes. In it for the long haul!

And you know what? Perka Buildings can LOOK GREAT TOO!

How does it get better!?

Building for the Future, NOW.

Martial L. Thevenot

Want a fancy porch?

Nice and cozy…

I know this is a church – but it shows brick finish and architecture…