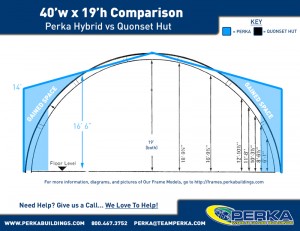

With a Prefab Perka Wood Steel Hybrid Building you not only get VALUE by the many great benefits and very asset driven features — but you get ADDED VALUE by the many aspects that eliminates waste in terms of time, money, convenience, comforts and even in potential liabilities or loss.

As you can see from the up to 21 great reasons (benefits) why you should consider building with a Perka Hybrid designed building that you can find here: http://www.perkabuildings.com/why-a-prefab-perka-hybrid-wood-steel-building/, here: http://www.perkabuildings.com/7-more-great-reasons-to-help-you-build-strong/, and here: http://www.perkabuildings.com/how-about-another-7-good-reasons-to-build-a-perka/, Perka’s unique approach to buildings offers you a very viable alternative to conventional buildings.

That said it also offers you MANY great SAVINGS from money, to time to just plain STOPPING ‘waste’!

If you just take a few minutes and look around WHERE YOU ARE sitting or standing this very minute, I am sure you can instantly see or count a number of things just being “wasted”. Anything from unfinished spoiling food, to cleaning up after damage from a storm, to a leaky faucet, to an open or unsealed door or window — often valuable resources, hard to find time and hard earned money are just literally being, and usually most reluctantly, and certainly rarely un-wilfully wasted away.

The men and women at Perka would like to think that they do whatever they can to help with a consciousness about these things. A kind of “closed loop” thinking… After all, “waste” just so happens to be a fairly important “pet peeve” of the stewards leading the way at Perka.

So what does that mean to you?

From the production/service standpoint Team Perka takes pride in a consciousness that encourages a total minimization of “waste” – taking into account the whole “system or process” of that effort. For that our costs are controlled while being able to still “afford” high levels of conscientiousness for quality.

For example most of the paper used at Perka headquarters is reused or recycle. From using the back side of no longer “good” paper, to using shredded paper for packaging, to bringing paper to the recycling stations. We keep costs in check – we can keep our price to you in check… That said – it must still nonetheless be done with an awareness of the total resource cost (entire loop) of doing so. i.e. if used paper is damage, filled with staples or otherwise not good for immediate use – there is awareness of the cost to “make right” that paper for re-use. So sometimes it’s not “worth” re-using or recycling if it will cost more to achieve that objective. Do you get the idea?

Similarly with its Building designs, fabrication, delivery, field assembly to materials use – a similar mindset is constantly encouraged and striven for. Of course we don’t live in a perfect world and “perfection” of this ideal is probably not a reasonable expectation. But the idea that there is awareness for this goal is tantamount to achieving any goal to minimize waste, maximize resources and optimize product output, use and satisfaction.

Stay tuned for more Blog posts in the coming days that will sharing more benefits about Perka Building designs that are not only asset optimizing but also waste and liability minimizing.