GIVE UP, GIVE IN OR GIVE MORE

“Winners Never Quit”.

With 7 important and invaluable tips to stay ahead of the curve.

How about this current experience that we ALL find ourselves in these days? What are you thinking?

If it were a football game or a hockey game, and we had just gone through a most disastrous quarter or period of scores/goals against, “turnovers”, “setbacks”, “uncertainties” and “injuries”, what would you do?

And what if the likely outcome for any sort of “victory” looked anything but probable let alone possible, what is the plan?

What are the options Coach? Give up? Give in? or Give more?

Would we GIVE UP and “quit” to just END THE GAME right there? Or would we GIVE IN and just go through motions to get this whole thing over with ASAP and start again another day? Or might we seek out to GIVE MORE, and crunch each moment into an opportunity to grow, to learn, to adjust, to evolve and maybe even to transcend into something even greater?

These can be things to make you go hmmm, eh?

If the 2020 Superbowl Champion Kansas City Chiefs, led by the remarkable phenom Patrick Mahomes, are an example of the potential impact of a GIVE MORE practice and mindset, then one can readily see that, even in the face of something even futile, applying consistent, determined, moment to moment, synergized effort, discipline and dare I say faith or belief, one can still “prevail” and overcome!! DO YOU BELIEVE?

Not unlike this Covid-19 pandemic, most of us are facing totally unexpected and unplanned-for setbacks, losses, changes, uncertainties and, for some, sickness (and God forbid, death). What do we do?

For many, who are probably some of the more fortunate ones, we are working from home. With all the possible disruptions we are enduring, we are still able to be and do something productive, in some form of comfort, that can still add value to our business, our job, our lives, our selves, our community, our world.

For some others, it is work, almost as usual. Albeit with social distancing protocols, hyper hygiene habits, though still in a factory, warehouse or job site setting. (And most thankfully, not a war zone.)

For a certain other group of strong, brave, devoted, courageous and no doubt dearly admired, appreciated and needed – they face daily overwhelm and un-bargained for risks, as they serve, every day, selflessly, to keep our world tended to, cared for, fed, sheltered or otherwise protected.

And yet for another group, most unfortunately, they are out of work, out of purpose, running out of resources and no doubt experiencing fear and an almost unbearable amount of uncertainty!

What do we do?

Thankfully, for those who are able and willing, there is an overwhelming consensus to reach out and help each other. Protect each other. Connect with each other. In fact, there are many businesses, not for profits, churches, service clubs, individuals and local governments – who are pro-actively seeking out to be our brother’s and sister’s keepers. #Inthistogether.

So, if you are reading this now, and are finding yourself in a place that knows not what to do, and would be served by some help with a call for you to seek out some sort of assistance – feel free to reach out to us. Team Perka is currently working with many agencies from Rotary International, to United Way, to Kiwanis, to the Optimist Club, to our Chamber of Commerce, to the Second Harvest Food Bank and with many of our family, local businesses, friends and neighbors to be on call to assist. No one needs to go through this alone. Resources from all sectors of our society are being deployed to help. Please call. Reach out. Ask!

And, if you are debating on what to do with your current new construction, retrofit, remodel or re-purpose of your building or expansion plans, there actually might exist, TODAY, HERE and NOW, a very good open opportunity of extra available time, readily accessible talents, more accessible resources and even lowered interest rates and costs that you could take advantage of immediately to still keep moving things forward, despite all the uncertainty.

I’d be remiss not to mention that most of the business leaders in our building industry are noticing a pent-up demand that is exponentially growing every day, which could literally and significantly bottle neck and possibly overwhelm schedules, especially once we do get an all clear. This is not unlike what is happening in New York, Michigan, California, Illinois, Louisiana and Georgia hospitals. – That said, pretty much EVERYONE believes we will get that ALL CLEAR, it’s just a question of when!

Our question is: where do you want to be when that happens?

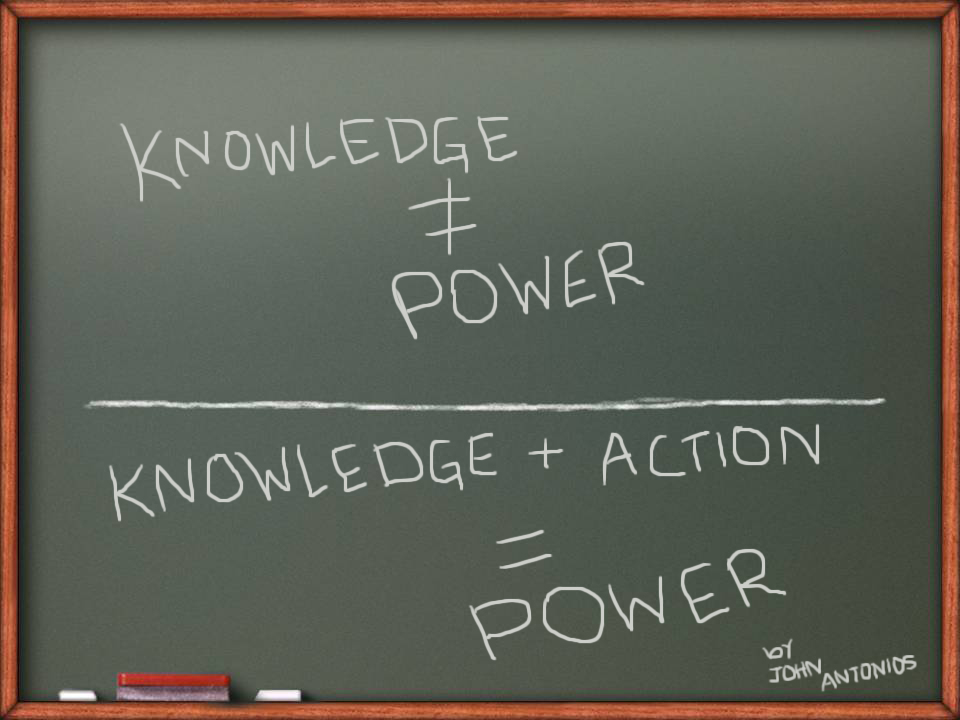

To help you stay ahead of that upcoming event, here are seven very important and very doable things you can initiate right now! TODAY!

- If you haven’t already done so, you may want to apply for the Economic Injury Disaster Relief (EIDL) advance. You could get a forgivable $10,000 in relief. (As of today’s writing, the system is already on overload and the demand will most likely cause for a fourth stimulus package, so it behooves you to get in that queue!) This one can take less than an hour to fill out. Even though it says allow 2 hours – some have done it in 15 minutes!! Click here: https://www.sba.gov/funding-programs/loans/coronavirus-relief-options/economic-injury-disaster-loan-emergency-advance

- If you are an entrepreneur, business owner, sole proprietor or even self-employed with one or more employees – you could also qualify for the Paycheck Protection Program (PPP). There too you could get forgivable loans to help you keep all your employees paid and on YOUR staff. For many of us it have been a big challenge to find and train great teammates. The last thing we want is to lose them! This will help everyone! Apply for that NOW! Fair warning: the queue line is growing there too. But as one of leaders in our industry said – it is FREE MONEY to help keep our teammates employed!? Who wouldn’t want to do that? Go here for that info: https://www.sba.gov/funding-programs/loans/coronavirus-relief-options/paycheck-protection-program-ppp. You will need to go through a SBA approved lender for this one. (*** As of 4/16/2020 – the allocated amount for this “phase” has run out and there is talk of adding more — the suggestion is to apply anyway – just in case!!)

- You can refinance any existing assets to take advantage of the current near zero interest rates. Your home, your office building, your church, your car, your warehouse, your home equity line – can all be possibly refinanced to new lower rates. Banks are poised to refinancing that could save you several hundred dollars or more every month!

- Get your new construction loan set up for your shouse, barn, garage, barndominium, warehouse, hangar, store, shed, arena, stables or dream home, ready to deploy as soon as you want. There could be several steps to this process. The sooner you start, the sooner you will have it done! As you can see from the above – banks will be extra busy for a while too. Don’t despair. GET IN THE QUEUE NOW ANYWAY! Inaction is NOT AN OPTION. At some point things will get back to some sort of new normal, — this is not the end of the world… so it behooves us to stay in motion! #KEEPMOVING… the motion can create a vacuum for attraction.

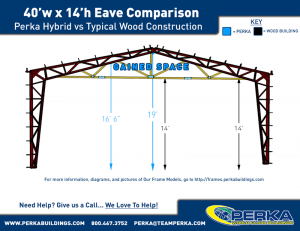

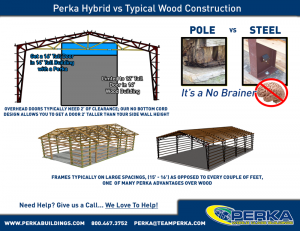

- Begin the research process of getting exactly what you want for your new structure. Strength. Affordability. Flexibility. Ease. Resilience. All very important factors to seek out and find out as much as you can about. With the help of a trusted building adviser you will not need to rush or worry into a most stress-free building solution, and make sure you get the one designed for you and your circumstances! You do not want to get this wrong! Ask questions. In fact, you can get a free white paper on the top 7 things to ask before you buy. Click here for that. You might invest a bit more time and money up front – but this will pay back MANY FOLD in use value, long term savings, asset appreciation, ease of construction, little or no changes or rework, flexible retrofits and in so many other ways.

- Get yourself into the ever growing queue of pre-orders for their building drawings and materials by getting yours written up, drawings detailed out and approved with your building department and permit offices NOW. While things appear to be slow in the overall economy and people planning — time is still of the essence! This too shall pass. In fact, for these code enforcement officers, while they may be working from home, they are actually responding quicker in relative terms, to most requests, Reason for this could be since there are less people acting on their plans and they are actually available! So, this would be a perfect time to get ahead on that.

- You can even begin on your site work (especially if you are DIY – Do-It-Yourselfer and are having to shelter in place at home), and can maybe even get the concrete poured right away; as we also know weather (rain, flooding, tornadoes, hurricanes, etc.) can also put a wrench into building and construction plans… And, in reality, with only so many GOOD concrete guys around (it is a very highly skilled craft – DO NOT CUT CORNERS HERE!), you will be well served to get that in, with the best contractor you can, when you can get it done, as soon as you can! This will help your builder who may have to change up his own queue by WHO IS READY TO GO NEXT!! (Being ready could also get you a break in labor costs if your timing is right and the contractor needs to fill a gap… many will cut margins to keep the flow!) A big key factor to this is COMMUNICATION! DO NOT WAIT – COMMUNICATE. The better you do this – the more stress free and actually enjoyable your experience will be.

Like the disaster relief funds that are being issued by the Federal Government CARES ACT, as big that number was, ($360 Billion) unfortunately, it appears that there won’t be enough to serve everyone. (Just added as of 4/8/20 from a phone presentation by Senator Roy Blunt (MO) – there might be an add on of $250 Billion more! – $70B has already been issued he said!) It was and is going to ever more be on a “first come first served” … so, it’s the doers and decision makers, – albeit calculated risk takers, who may very well come out of this ordeal on the better end of the recovery phase. (*** As of 4/16/2020 – the allocated amount for this “phase” has run out and there is talk of adding more — the suggestion is to apply anyway – just in case!!)

As we might expect, there is definitely some pent up demand in so many ways of so many things… from going to restaurants, to theaters, to beaches, parks, parties, bars, weddings, birthdays, vacations, holidays, you name it… people are chomping at the bit to “get out”. While this experience may be dampening spirits for now, today, when we begin to get back to some sort of normalcy – people will be wanting to get out like it was the last day of high school – free for summer vacation! Even if it’s not an ALL CLEAR – there will be some line up queues forming! Where do you want to be?

It behooves those who can, and this looks very much like YOU who is still reading this now, the optimist, the hope filled spirit, the planner, the wise, the more fearless, the hungry, the doer, the person of ACTION – to KEEP ON MOVING, even if it’s small steps every day. To quote Mike Dooley from TUT – “Your Zenith of Magnificence awaits”!

NOTHING IS PERMANENT.

We too here at TEAM PERKA, are planning on this to pass…, because it will. We take steps every day. Making conscious choices and thought out decisions that will bring us closer to our goals, our intentions, our vision, our dreams, every single day. The “destination” is actually the Journey. Our purpose is to seek out the most Stress-free Solutions while Trusting Sincere Selfless Service. #sssTsss.

Being a big fan of Simon Sinek, our intentional “WHY” culture at TEAM PERKA does rely a lot on this all being an Infinite Game.

So, we strive every day:

- To wake up every morning enthusiastic, inspired an engaged.

- To go through each and every one of those days on purpose, energized, lifting up our families, our mates, our friends, our neighbors.

- To go to bed at night feeling fulfilled and satisfied from a day well spent!

Are you with us? Are we truly in this together? Even though temporarily apart?

Call us, – we want to help you tap into your reservoirs of tenacity, understanding and asset building for the future of your homestead, your business, your family, our community and our world! Let’s do this!

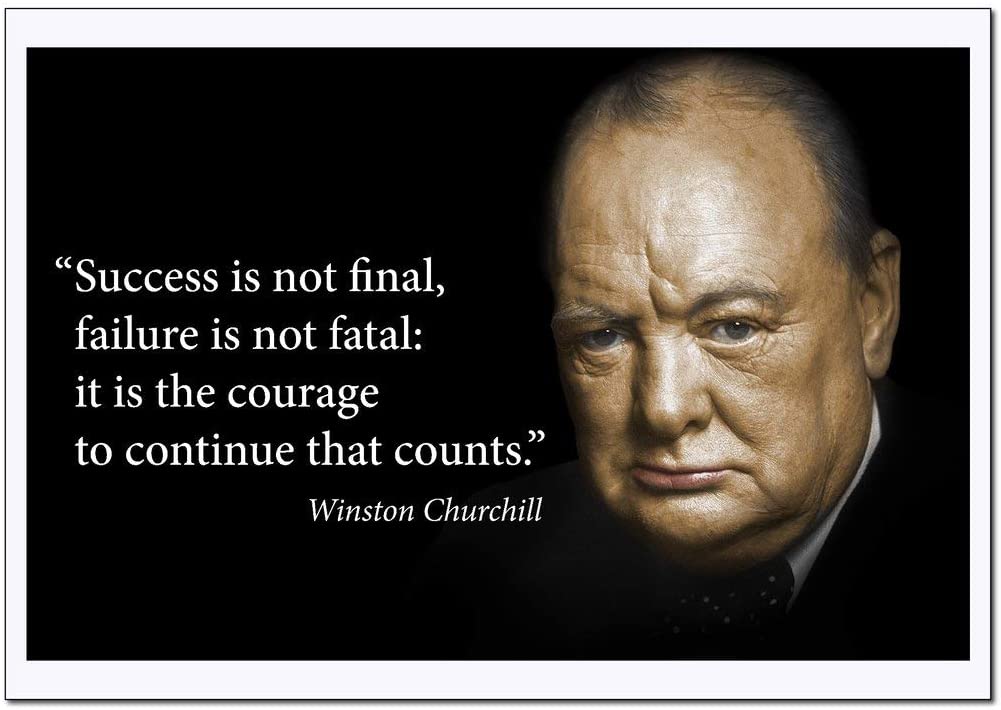

Former British Prime Minister, Winston Churchill, has been attributed to saying, “Success is not final; failure is not fatal. It is the courage to continue that counts.”

Former British Prime Minister, Winston Churchill, has been attributed to saying, “Success is not final; failure is not fatal. It is the courage to continue that counts.” Of course, it’s perfectly acceptable to take a break after a big success, sharpen the axe so to speak… unless it becomes a constant excuse. Sometimes we push ourselves so far backwards after a success that we wind up worse than before!

Of course, it’s perfectly acceptable to take a break after a big success, sharpen the axe so to speak… unless it becomes a constant excuse. Sometimes we push ourselves so far backwards after a success that we wind up worse than before! At Team Perka, we would love to be a part of helping you achieve your building goals!

At Team Perka, we would love to be a part of helping you achieve your building goals!

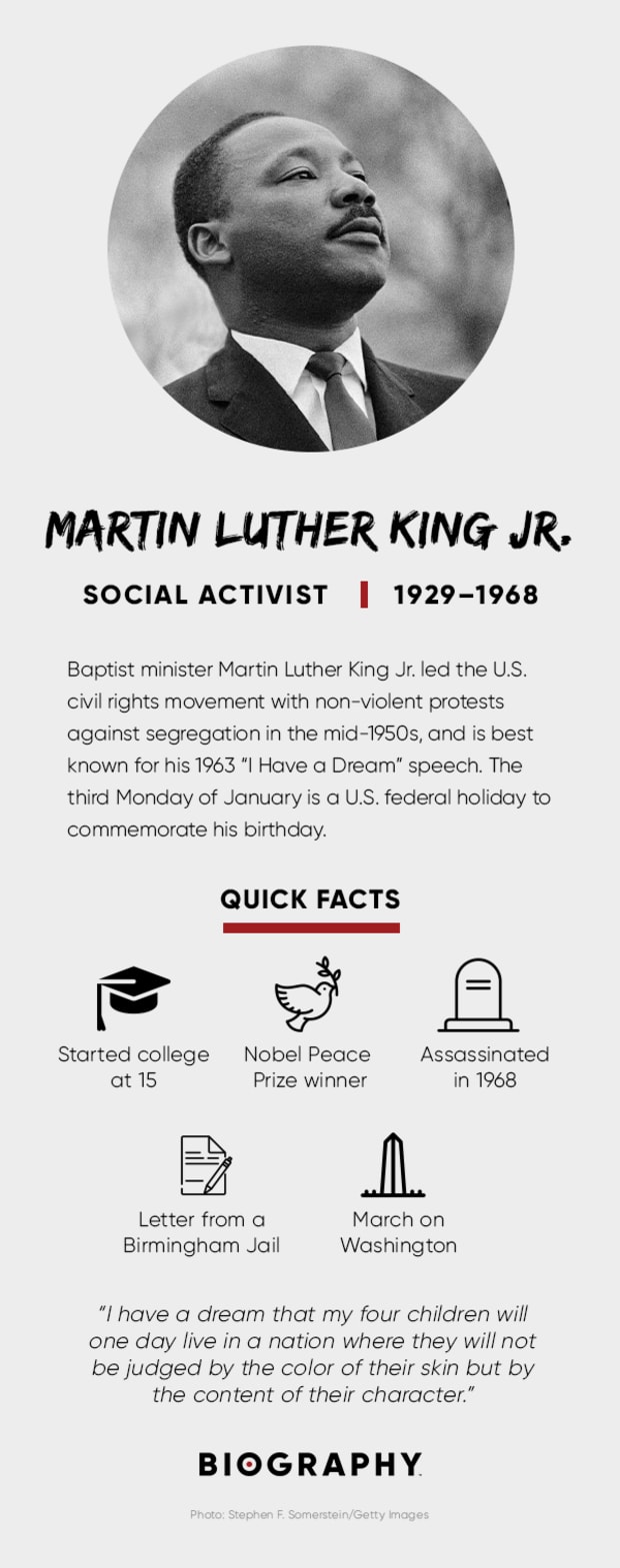

There had already been one attempt made on his life, as well as attacks to his home. But MLK didn’t let that stop him. Throughout his life, he organized several boycotts and peaceful protests to raise awareness for his cause and even won a

There had already been one attempt made on his life, as well as attacks to his home. But MLK didn’t let that stop him. Throughout his life, he organized several boycotts and peaceful protests to raise awareness for his cause and even won a  But, of course, Martin Luther King, Jr., was a man most famous for his dream, that is, his

But, of course, Martin Luther King, Jr., was a man most famous for his dream, that is, his

While we may not be able to go visit our loved ones this year, we live in an age of technological marvels. Anyone up for a family

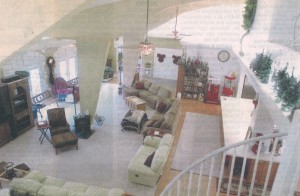

While we may not be able to go visit our loved ones this year, we live in an age of technological marvels. Anyone up for a family  If you have ever owned one of Perka’s unique hybrid buildings, you know how VERY spacious they can be. (They are customizable, with large free and clear spans for breathtaking rooms, and these incredible structures can be as large or as small as you please!)

If you have ever owned one of Perka’s unique hybrid buildings, you know how VERY spacious they can be. (They are customizable, with large free and clear spans for breathtaking rooms, and these incredible structures can be as large or as small as you please!)

“When life gives you lemons, make lemonade.”

“When life gives you lemons, make lemonade.”  Tip 1:

Tip 1:

Tip 3

Tip 3 Tip 4:

Tip 4: Tip 5:

Tip 5:

In 1959, American football coach and legend

In 1959, American football coach and legend

can mis-use our time that could better be used to focus on our goals. That is why Team Perka is here for you.

can mis-use our time that could better be used to focus on our goals. That is why Team Perka is here for you.

If you have read this far, you’re probably curious as to why we’ve been talking about collation and “keeping up with the Joneses” (or any other families who happen to live next door to you). What does this have to do with buildings? Well, it’s because of Perka’s dedication to our customers: to YOU. The products and services we offer are part of the bigger picture goal of wanting to make our world better… To serve man and woman kind!

If you have read this far, you’re probably curious as to why we’ve been talking about collation and “keeping up with the Joneses” (or any other families who happen to live next door to you). What does this have to do with buildings? Well, it’s because of Perka’s dedication to our customers: to YOU. The products and services we offer are part of the bigger picture goal of wanting to make our world better… To serve man and woman kind!

Let’s begin at the farm, the actual source of our entire food supply chain. (No, it’s not the “store”!!)

Let’s begin at the farm, the actual source of our entire food supply chain. (No, it’s not the “store”!!)  One Pennsylvania farmer, Mr.

One Pennsylvania farmer, Mr.